6 min

6 min

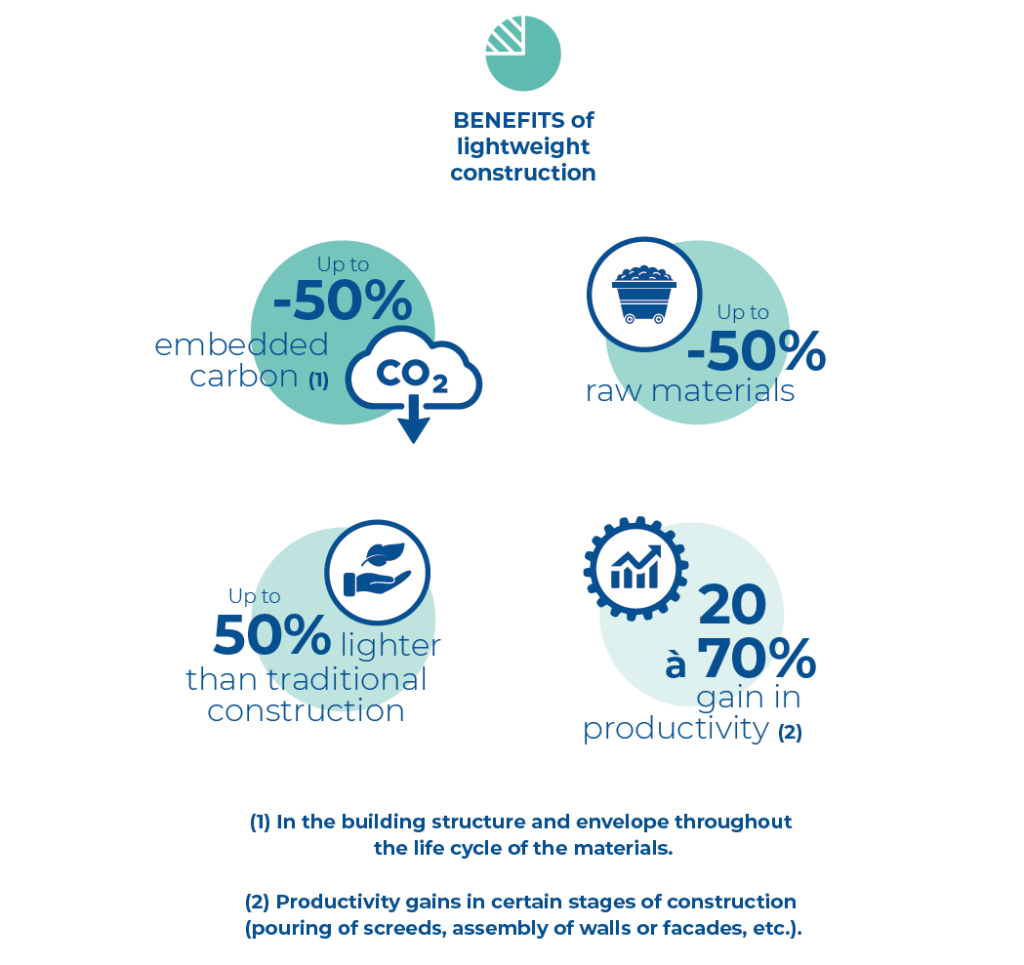

In contrast to conventional methods, which favor structures with load-bearing masonry walls (made of stone, concrete or brick), light construction uses lighter load-bearing structures in the form of wooden, metal or concrete “skeletons,” to which non-load-bearing facade and partition systems are attached. And that changes everything! It significantly reduces the consumption of natural resources and the building’s carbon footprint. Professionals see a dramatic reduction in construction time and an increase in productivity. Lastly, users benefit from greater comfort and flexibility when they take up occupancy.

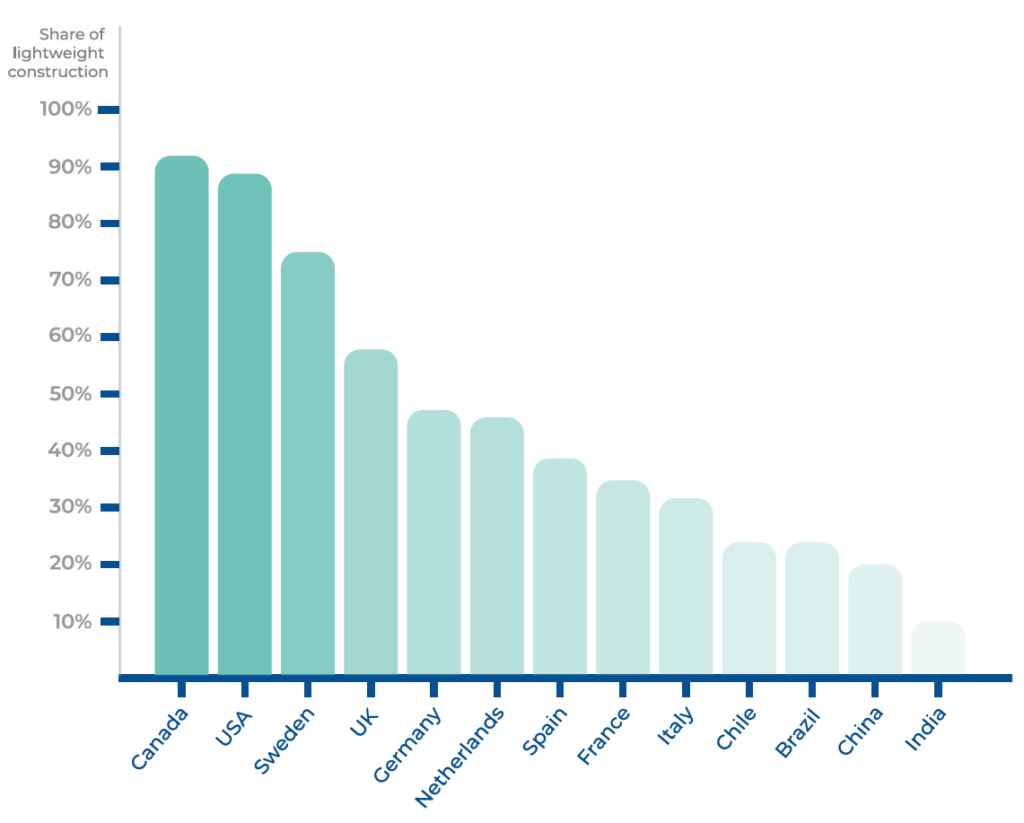

Different realities around the world

Light construction varies greatly from one country to another, and this is its great strength. How and why it is adopted differs according to the availability and cost of materials, the level of training of professionals, the sustainability culture in the country and the market need for residential or non-residential buildings.

In some countries where it is still in the adoption phase, light construction is gaining ground based on the economic advantages it brings to projects, in particular through reduced transport costs for materials, shorter construction times and simplified assembly of pre-assembled components. It also increases the market value of buildings by optimizing their energy efficiency and helping to limit maintenance costs.

In countries where government initiatives encourage more sustainable solutions, or impose strict environmental standards, light construction is chosen for its superior performance in terms of circularity (better planned and optimized consumption of resources, dismantlability, recyclability, re-usability) and for the reduction in embodied carbon and energy it provides. Light construction also reduces building site waste by using less raw material, or by taking advantage of pre-assembled frameworks that can be manufactured and assembled more precisely off-site.

SEE ALSO: THE TWO SIDES OF CARBON

Some light construction practices using wood, metal or concrete

The use of wood in lightweight construction is common in many countries in North America and Northern Europe, where it is an affordable and readily available resource, and where forest management has ensured the sustainability of the solutions used. From an energy point of view, the use of wood in the structure of lightweight buildings reduces heat loss through thermal bridges, for example where two walls meet.

Another popular light construction technique is Light Gauge Steel Framing (LGSF), which is prefabricated off-site, then easily transported and quickly assembled, saving time and money over the entire project. This offers many environmental advantages. As LGSF is often made from recycled materials, construction projects do not require the production of new steel. And, at the building’s end of life, the same steel can be recycled again, promoting circularity and waste reduction.

Concrete also has a role to play in light construction. While it is often disparaged, there are now solutions to make it more compatible with the requirement for decarbonization. Weber, for example, has taken a proactive approach by reducing the cement content of its formulas through the use of wasterials. This is a circular and virtuous approach that reduces the carbon footprint of concrete. The aim is to replace 60% of cement by blast-furnace slag from steel production and fly ash from coal-fired power stations by 2030.

ALSO READ: Reinventing concrete

What does the future hold for light construction?

With its reduced environmental impact combined with increased circularity, modularity and flexibility, light construction is set to make its mark on our cities. It could speed up the race to decarbonize construction and renovation, and make it easier to meet the growing demand for healthy, sustainable housing.

The levers for its development depend on the reality in each country, but some common factors emerge. Above all, light construction needs to be better known by all players in the construction sector, and better understood through the acquisition of the right skills. In addition, there are some obstacles to be overcome, with regulations that provide greater incentives and are designed to last, better cost control and more accessible LCA (Life-cycle assessment) data.

DISCOVER ALSO: L... FOR LCA

Photo credits: Kristin Spalder / Shutterstock.com; Picxy.com/munna; Stadthaus, Murray Grove. Image fournie par KLH UK; Ecolit Construction Systems