SUSTAINABLE BUILDING SITES, 11 BEST PRACTICES

Integrating sustainability into a building project is no easy matter! From project analysis to choosing the suppliers, from the buildings’ structure and envelope to air renewal, down to construction waste management...

Here are the best practices for a sustainable building project in 11 steps.

-

1/ PROJECT FEASIBILITY

The project begins with drawing up technical specifications to establish the project’s feasibility.

Survey excavations are carried out on the ground.

Aim: gather scientific data, protect biodiversity, and safeguard any archeological elements.

-

2/ PROJECT ANALYSIS

The building’s decarbonization and circularity are considered from start to finish of the project, taking the materials’ whole life cycle analysis into account.

Taking the building’s climate approach into account, considering its modularity.

Can it easily be deconstructed?

Converted for another use?

-

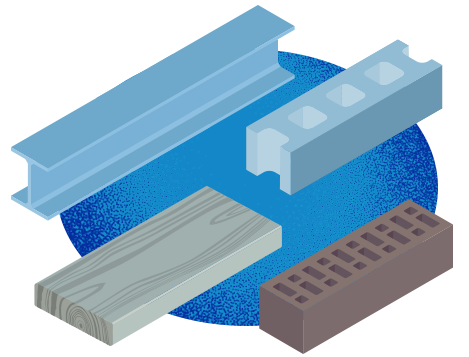

3/ CHOICE OF MATERIALS

To reduce the carbon footprint and conserve exhaustible resources, the choice is made to reuse construction products and adopt light building solutions and recyclable materials.

Choosing products with a high recycled or renewable material content with sustainable and optimized packaging.

-

4/ SELECTION OF SUPPLIERS

Taking the sustainable building path also means choosing responsible suppliers with ambitious environmental and social goals.

Prioritizing local suppliers to take the impact of transport to the site into account.

-

5/ PROJECT PLANNING

Using the BIM model facilitates information sharing throughout the project.

BIM (Building Information Modeling) can be used to optimize a building’s efficiency, better choose its materials, and assess its impact, in conjunction with Life Cycle Analysis and energy simulation tools.

-

6/ THE FOUNDATIONS AND STRUCTURE

Choosing a cement made from “wasterials” (co-products from other industries, such as ash or blast furnace slag = mix of non-ferrous oxides from cast iron manufacture) to produce a concrete whose carbon footprint is reduced by up to 70%.

A light building structure that combines steel, wood, and concrete.

-

7/ THE BUILDING’S ENVELOPE

The facades, exterior walls, and roofs are well-insulated and airtight.

The double or triple glazing has low emissivity. The whole building offers high acoustic comfort.Solutions delivering lightweight facades made of plasterboard and mineral wool offer a reduced carbon footprint and consume fewer resources.

-

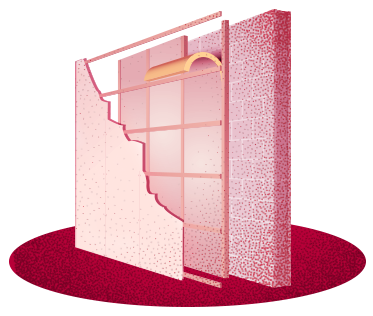

8/ PARTITIONS

Preference is given to light framed plasterboard partitions, combining glass wool insulation with a bio-based binder to preserve the air quality and enhance the acoustics.

Pre-cutting in the factory reduces waste and kitting and makes it possible to deliver the right amount of materials.

-

9/ AIR RENEWAL AND VENTILATION

As the building is well sealed, the air must be continually renewed by opening windows or providing mechanical ventilation.

Balanced ventilation with heat recovery makes it possible to considerably reduce energy consumption during air renewal.

-

10/ HOT WATER, HEATING AND COOLING

Equipment is chosen that is powered by low-carbon or renewable energy, such as a solar water heater or wood-fired boiler.

A geothermal heat pump consumes very little energy to heat space and water and cools indoor air in summer.

-

11/ CONSTRUCTION AND DECONSTRUCTION WASTE

The construction of a sustainable building also involves addressing waste management/valorization on the site and at the building’s end-of-life.

Sorting waste at source on the site to facilitate its reuse or recycling notably delivers economic, environmental, and technical benefits.